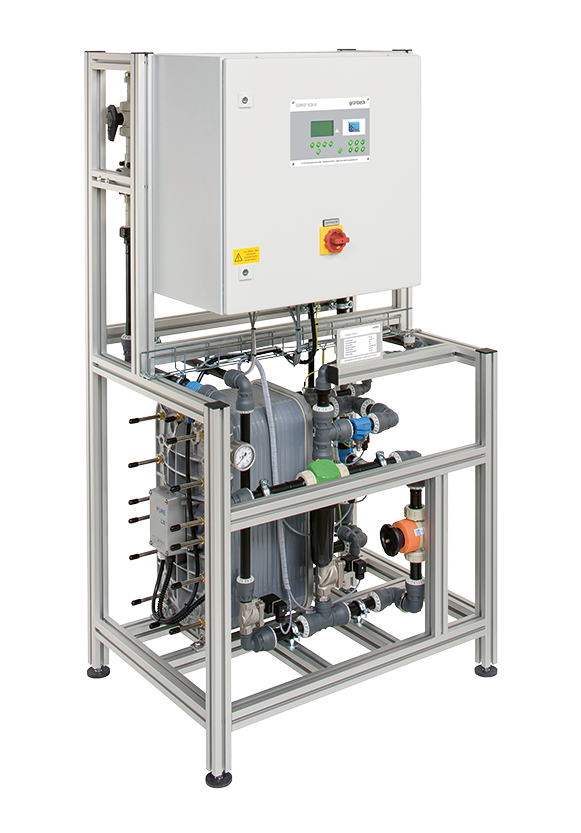

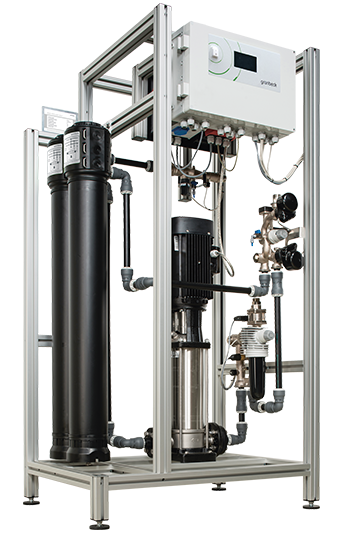

Specialist in industriële waterbehandeling

Schoon water is een van de grootste uitdagingen van de 21e eeuw. Veel industriële branches zijn voortdurend op zoek naar nieuwe oplossingen voor een veilige, betrouwbare en duurzame watervoorziening. Deze oplossingen moeten ook bijdragen aan duurzaamheid door het verhogen van de efficiëntie en een vermindering van het waterverbruik. Onze waterbehandelingsoplossingen doen alle drie, elke dag. Bij Grünbeck geloven we in kwaliteit en duurzaamheid. Al onze producten zijn ontworpen, geproduceerd en getest op ons hoofdkantoor in Duitsland.

Kies voor Grünbeck Waterbehandeling

Standaard modulaire oplossingen

- Korte projectplanning en levertijden dankzij onze modulaire oplossingen.

Kostenefficiënt

- Dankzij onze hoge mate van standaardisatie kunnen we concurrerende prijzen bieden voor onze producten van hoge kwaliteit.

Hoge uptime & duurzaamheid

- Grünbeck staat voor engineering van hoge kwaliteit, gemaakt in Duitsland.

Duurzame oplossingen

- Verminder het gebruik van energie, zout en chemicaliën met onze zeer innovatieve systemen.